What is WPC? A sustainable innovation for outdoor design

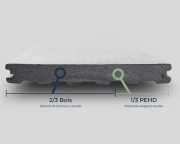

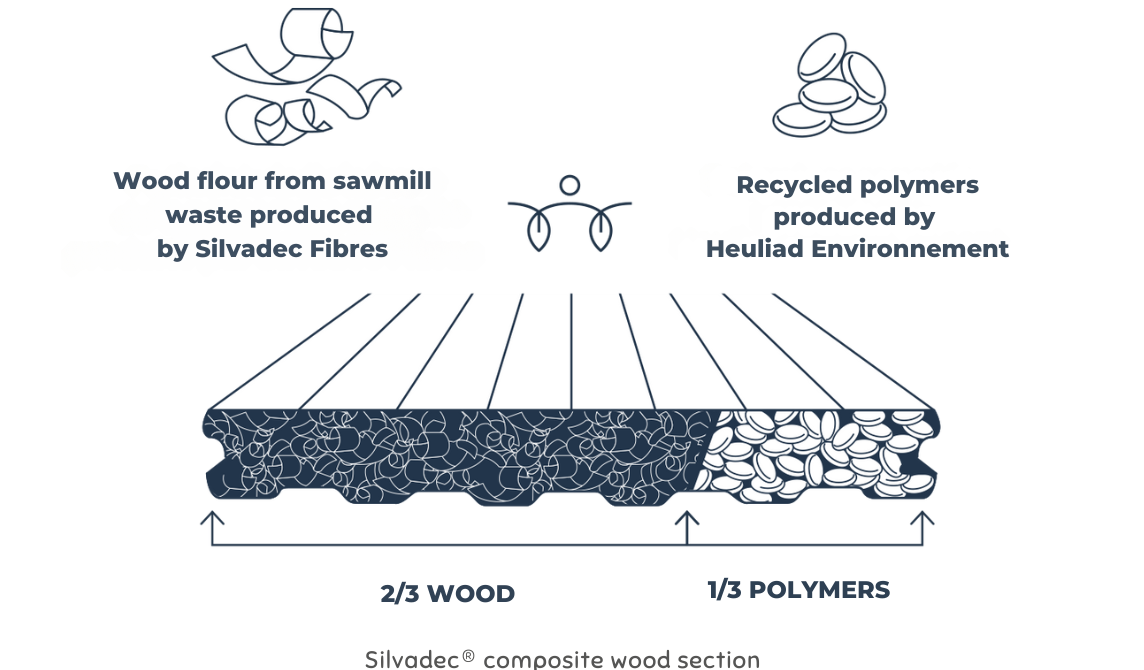

WPC (Wood Plastic Composite) is an innovative material that combines wood flour with a polymer material. This unique alliance merges the natural appearance of wood with the exceptional strength of modern polymers.

Silvadec, French WPC manufacturer since 2001, deploys industrial expertise inspired by North American standards, adapted to European market requirements. As a European pioneer, Silvadec has paved the way for these technical solutions for outdoor design (decking, cladding, screening), establishing new performance benchmarks against traditional natural wood species.

Silvadec® WPC composition, unique for its exceptional performance

- Approximately 2/3 PEFC-certified wood fibres: Sourced from French Maritime Pine and Sitka Spruce, these fibres give the material a natural and authentic appearance while ensuring responsible sourcing.

- Approximately 1/3 high-performance polymer: This polymer provides WPC with excellent UV resistance, exceptional durability and recyclability.

- Innovative specific additives: Carefully selected, they enhance the WPC material's UV stability and offer optimal protection, ensuring its longevity and the preservation of its aesthetic properties over time.

Result of 20 years of development, this composition with a large wood majority offers a material with superior properties, meeting the strictest requirements of professionals and homeowners.

Innovative manufacturing processes

Our manufacturing facility controls two distinct industrial methods for producing wood-polymer composite profiles

Monoextrusion technology

Extrusion is the basic process used for manufacturing Silvadec WPC:

1. Mixture preparation

Wood fibres (from sustainably managed French forests), high-quality recycled polymers and additives are mixed to form homogeneous granules.

2. Extrusion process

- The granules are fed into an extruder, a long heated tube containing one or more screws.

- Under the effect of heat and pressure, the mixture melts and becomes malleable.

- The screw pushes the molten material through a die that gives the final product its desired shape.

3. Cooling and finishing

- Upon exiting the die, the extruded profile is rapidly cooled to set its shape.

- It is then cut to the desired length.

Coextrusion technology

Co-extrusion is an advanced technique used by Silvadec to further enhance product performance:

1. Co-extrusion principle

- Use of two or more extruders operating simultaneously.

- Each extruder produces a different layer of the final product.

2. Application to WPC

- The core of the profile is manufactured with the standard Silvadec® WPC blend.

- An outer layer is simultaneously extruded (co-extruded) around the core.

3. Advantages of co-extrusion

- Improved UV resistance, stain resistance and surface texture.

- Ability to create colour nuances and finishes more closely resembling natural wood, as in our Atmosphère Nuances range.

- Increased overall durability of the product.

we design a unique, eco-friendly and recyclable material.

Élégance and Émotion

Range

MONOEXTRUSION

Atmosphère

Range

COEXTRUSION

Did you know?

Over 1 million m² of decks installed every year, demonstrating our customers' confidence in Silvadec quality.

French manufacturer: we design and produce our solutions ourselves, unlike mere importers.

French production: all our composite boards are manufactured in our Arzal factory in France.

Why choose WPC as an outdoor design solution? Discover its 10 main advantages

Silvadec® WPC is an innovative material with numerous advantages:

1. A durable material

- Silvadec® WPC products are guaranteed for 25 years. They come in decking boards, fencing and cladding.

- Durability multiplied by 2 compared to natural wood

2. Resistant

- High resistance to weather variations, rain, frost and wind

- Reduced risk of warping, swelling or cracking

- High abrasion resistance (comparable to Oak according to Wood Technology Centre tests)

3. Rot-proof

- Guaranteed for 25 years against termite, insect and fungal attack

- Moisture resistant

4. Stable colours

- No treatment required, no oil: colours will be stable over time

- Numerous colours available: brown, grey, ipe, black (in fencing)…

- Resists fading that could be caused by UV sunlight and pool chlorine.

5. Easy maintenance of decks, fences and cladding

- Cleaning with soapy water at least once a year is recommended

- No need for expensive wood oil

6. Slip-resistant and splinter-free

- Limits fall risks

- Ideal for pool surrounds

- No risk when used barefoot

- Comfortable and safe for children (certified "toy safety" according to standard EN 71-3:2019)

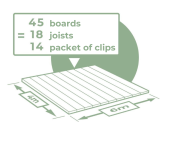

7. Easy installation

- Easy to work with (same tools as solid wood)

8. Medium-term economy

- Its initial investment pays for itself over time due to its low maintenance and durability.

9. Certified environmental approach

- Avoids cutting and transporting tropical wood

- 100% recyclable at our production site

- End-of-life board recovery through the recompose-it programme

- Meets numerous environmental standards

10. Versatile and adaptable

- Suits all project types: residential and commercial

- Compatible with different architectural styles

- Suitable for decking, fencing and cladding

Please note!

Exclusive solid boards: All our decking boards are solid boards, guaranteeing exceptional resistance to heavy loads up to 500kg/m² for uniformly distributed load and 200kg for concentrated load, unlike competing hollow boards.

Preserved exotic wood aesthetics: Our technology, unique in Europe, faithfully reproduces the authentic appearance of exotic wood, without the characteristic greying of traditional wood.

Simplified installation: Whether for decking, fencing or facades, benefit from a complete system of dedicated accessories, clips and profiles specially designed to facilitate installation.

Safety and environment: our commitment to sustainable and healthy composite

Healthy and safe composition

- Guaranteed free of harmful substances: Complete absence of heavy metals in our formulation.

- Non-toxic material: Safety guaranteed for daily use outdoors and indoors.

Controlled environmental impact

- Responsible production: Optimised manufacturing process with low energy consumption.

- Short supply chain: 100% French production limiting carbon footprint from transport.

- Circular economy: Use of recycled materials and development of the recompose-it programme for end-of-life recycling.

Certifications and compliance

- Proven safety: "Toy safety" certification attesting to the total harmlessness of the material.

- Environmental excellence: Compliance with the sector's most demanding environmental standards.

Applications and Uses

Composite wood boards and fencing offer remarkable versatility in outdoor design, adapting well to residential spaces and pool areas as well as public facilities, balconies in multi-unit housing, business spaces, and even nautical applications.

PRIVATE PLACES

POOL AND RELAXATION AREAS

PUBLIC ACCESS BUILDINGS

BALCONY TERRACES

BUSINESS SPACES

BOAT PARTS

FAQ: Understanding Composite Wood and Silvadec Expertise

What is composite wood made of?

Composite wood is a modern material combining wood fibers and polymer. Silvadec, a European pioneer since 2001, distinguishes itself with an optimal composition of 2/3 PEFC wood fibers (French Maritime Pine and Sitka Spruce) and 1/3 polymer.

Unlike competing compositions using hollow materials, this unique formulation guarantees exceptional resistance to loads (up to 500kg/m²) thanks to solid boards, while ensuring total recyclability of the product.

What is the lifespan of composite wood?

The lifespan of composite wood varies depending on manufacturers and their production processes. Silvadec stands out with a 25-year warranty on its products, which is double the durability compared to natural wood and superior to market standards.

This performance is based on technology proven in the United States and perfected for the European market, particularly through co-extrusion, an advanced technique rare in the industry.

How is composite wood manufactured?

Composite wood manufacturing uses various technologies. Silvadec masters two innovative manufacturing processes in its French and German factories:

- Traditional extrusion, optimized for responsible production with low energy consumption

- Co-extrusion, a cutting-edge technology providing a double protective layer, where many manufacturers are limited to simple extrusion

This industrial expertise, rare among European manufacturers who are often simply importers, allows Silvadec to control the entire production process.

How does composite wood age?

The aging of composite wood heavily depends on its composition and manufacturing process. Silvadec's technology, unique in Europe, guarantees:

- Color stability without the characteristic graying of traditional wood

- Superior resistance to UV rays thanks to specific innovative additives

- No deformation, unlike competing hollow boards

- Minimal maintenance compared to other outdoor design solutions

Is composite wood rot-proof?

The rot-resistance of composite wood varies according to its composition. Silvadec's formulation, free of heavy metals, offers a 25-year guarantee against biological attacks, whereas many competing products present risks of long-term degradation.

This performance is validated by strict certifications, notably the "toy safety" certification attesting to the total safety of the material.

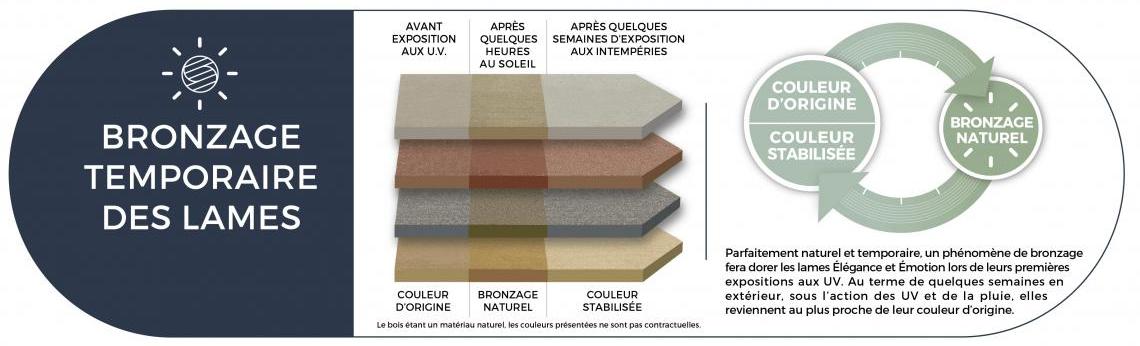

Why do my Elegance and Emotion boards yellow after installation?

The yellowing observed on Elegance and Emotion decking boards is a temporary weathering phenomenon, perfectly natural for composite wood.

This natural phenomenon occurs during the first weeks following installation and gradually disappears after exposure to sun and weather. Eventually, the boards will return to their original shade and their color will stabilize.

In semi-sheltered or sheltered areas, this process may take longer due to reduced exposure to UV and natural elements.

If moisture rings persist, it is possible to accelerate their disappearance by using a water jet and a scrub brush, brushing in the longitudinal direction of the boards.

What are the main applications of composite wood?

Composite wood has many applications in outdoor design. Silvadec distinguishes itself with a complete range of solutions developed and produced in France:

- High-resistance decking with exclusive solid boards

- Fencing and cladding systems with dedicated accessories

- Special arrangements for demanding environments (swimming pools, public spaces)

- Certified architectural solutions for the professional sector

The 100% European production and the recompose-it program for end-of-life recycling demonstrate Silvadec's superior environmental commitment compared to imported solutions.