Environmental Performance: A Responsible Choice

Silvadec composite cladding fully embraces a sustainable and eco-responsible construction approach, addressing current environmental challenges.

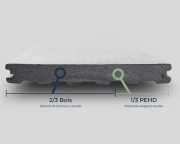

Eco-friendly and Durable Composition

The Silvadec composite wood is primarily made from wood fibers sourced from sustainably managed forests, as certified by the PEFC label on our products. This certification ensures that the wood comes from forests where biodiversity is preserved and regeneration is guaranteed.

Our composite’s specific formulation results in a highly durable material, reducing the need for frequent facade replacements and the use of additional resources. The product’s exceptional longevity (over 25 years) represents a major environmental advantage by significantly lowering the carbon footprint over the building’s entire lifecycle.

Local and Responsible Production

Manufactured in our factory in Brittany, Silvadec composite claddings benefit from a short supply chain that minimizes the environmental impact of transport. Our production site, part of the Bois de France network, is ISO 14001 certified, demonstrating our commitment to an effective environmental management system.

Our manufacturing process has been optimized to reduce energy consumption and limit CO2 emissions. Additionally, we recycle production offcuts internally, thereby minimizing industrial waste.

Absence of Toxic Treatments

Unlike traditional wood, which often requires chemical treatments to withstand external aggressions, Silvadec composite cladding requires no preservation treatments. This feature eliminates the use of potentially toxic substances harmful to both the environment and health.

Maintenance of the composite cladding requires no solvents or chemicals—only clean water—significantly reducing the environmental impact over the product’s lifespan.

Contribution to Building Energy Efficiency

Used in combination with external thermal insulation (ETICS), Silvadec composite cladding helps improve the building’s energy performance. This solution reduces thermal losses, thereby decreasing energy consumption and associated greenhouse gas emissions.

Used in combination with external thermal insulation (ETICS), Silvadec composite cladding helps improve the building’s energy performance. This solution reduces thermal losses, thereby decreasing energy consumption and associated greenhouse gas emissions.

End-of-Life Management

At the end of its life, it is important to note that:

- Burning composite wood in the open air is prohibited (Article 84 of the Departmental Sanitary Regulations)

- Silvadec discourages its use as fuel in boilers or barbecues due to the significant production of slag

Silvadec products can only be recycled at the production site through the ecobox by Silvadec available at our distributors.

European and French Standards

Silvadec composite cladding meets the requirements of the following standards:

- Eurocode 1 - Actions on structures (EN 1991): defines the mechanical forces the facade must withstand (wind, snow, impacts)

- Eurocode 5 - Design and calculation of timber structures (EN 1995): establishes calculation and sizing rules for wood and derivative structures

- DTU 41.2 - Exterior wood claddings (for France and overseas territories): unified technical document governing the installation of wood and derivative claddings

Regulatory Aspects Concerning Safety

As a professional or project owner, the overall safety of your project is crucial. When selecting facade materials, it is essential to consider all regulations applicable to your specific project.

For any project requiring specific performance, particularly for public buildings (ERP) or mid- to high-rise buildings, we invite you to contact our technical department, which will guide you toward the most suitable solutions for your situation and local regulatory requirements.

Local and regional specificities:

- Seismic zones: specific recommendations may be necessary

- Coastal zones: for sites less than 3 km from the sea, prefer A4 stainless steel fasteners for optimal corrosion resistance

- Local planning and urban regulations (PLU): some municipalities impose specific aesthetic or technical constraints (colors, materials, etc.)

Used in combination with external thermal insulation (ETICS), Silvadec composite cladding helps improve the building’s energy performance. This solution reduces thermal losses, thereby decreasing energy consumption and associated greenhouse gas emissions.

Used in combination with external thermal insulation (ETICS), Silvadec composite cladding helps improve the building’s energy performance. This solution reduces thermal losses, thereby decreasing energy consumption and associated greenhouse gas emissions.